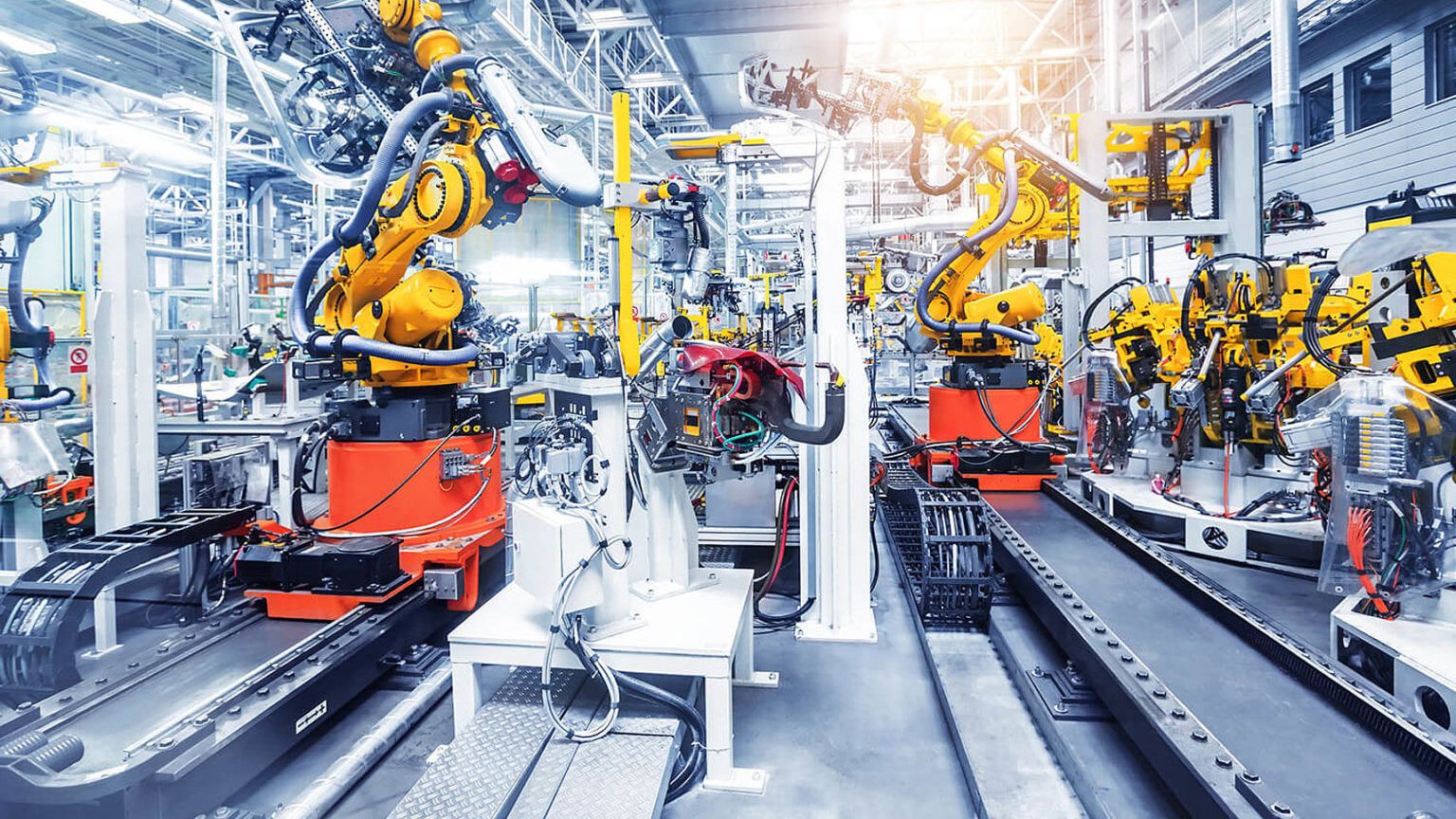

Automation of production processes

Automation of production processes is a strategic direction in the modernisation and technological renewal of production facilities of enterprises. This process includes the introduction of automated systems and equipment capable of independently performing programmed tasks, analysing the obtained data and, if necessary, adjusting their work in accordance with changing conditions or production parameters.

Automation is based on the principle of minimising human involvement in routine, hazardous or high-precision operations, which not only increases labour safety but also helps to reduce human error. Automation ensures the continuity of production processes, their predictability and controllability, which is the key to stable quality of the final product.

Objectives and basic principles

The main objectives that are achieved by automating processes in a manufacturing plant are as follows:

- Reduced costs: automation reduces labour, energy and raw material costs by optimising production processes and reducing waste.

- Increased productivity: 24/7 production is possible without loss of quality and productivity, which is unattainable with purely manual labour.

- Improved product quality: automated systems ensure high process accuracy and repeatability, resulting in improved product quality.

- Flexible control: this means that production lines can be quickly adapted to new tasks and working conditions, and production flows can be efficiently managed to meet changing demand.

Automation is based on the following principles:

- Integration: automation systems should be integrated with other enterprise information and management systems to provide a unified information environment.

- Flexibility and scalability: such systems should be easily adaptable to changes in the production process and allow for the phased introduction of new functions and tasks.

- Reliability and safety: a key aspect is the creation of systems with a high level of reliability, capable of preventing accidents and malfunctions and guaranteeing the safety of personnel.

- Efficient data management: automation involves collecting, storing, processing and analysing large amounts of data, which requires the development of efficient algorithms for processing and protecting them.

Automation tools in production

In today's manufacturing environment, automation plays a key role in improving efficiency and optimising work processes. Let's take a look at the main tools that are widely used at enterprises in various industries.

Hardware and software system

Hardware and software systems integrate high-performance hardware and specialised software for monitoring, controlling and optimising production processes. These systems can include industrial controllers, sensors, actuators and human-machine interfaces, thereby ensuring that production processes are highly flexible and adaptable to changing conditions and requirements.

Flexible Manufacturing Systems (FMS) and numerically controlled machines

Flexible Manufacturing Systems (FMS) is an advanced automation concept that combines CNC (numerical control) machines, automated material storage and transport systems as well as systems for rapid tool and tooling changes. FMS are capable of adapting to different production tasks independently, which makes it possible to manufacture a variety of products on the same line with minimal time-consuming changeovers.

Automated lines

The core of mass and serial production are automated production lines, which consist of sequentially connected workstations that perform a certain set of operations on the product. The movement of parts between stations is automatic, without human intervention, which ensures high speed of the production process and reduces the probability of defects.

SCADA

SCADA (Supervisory Control And Data Acquisition) systems are designed to monitor, collect and analyse data from various production areas in real time. They provide operators with centralised access to information about equipment operation, allowing them to react to emerging problems in a timely manner, analyse performance and optimise processes.

Robots

The introduction of industrial robots into production processes makes it possible to automate many operations, from simple and monotonous to highly precise and potentially dangerous for humans. Robots can be equipped with various devices such as grippers, welding torches or material handling tools, making them indispensable aids in modern manufacturing.

Each of these automation tools plays a role in improving the efficiency, quality and safety of production processes.

Levels of automation of production processes

The division into levels reflects the degree of adoption of technologies and systems that ensure autonomy and efficiency of operations in the enterprise. The distinction between levels shows the path from traditional manual methods to fully automated production, where technological innovation takes the main role in performing tasks.

- Zero level of automation is characterised by the complete absence of automated systems, where all production processes and operations are performed manually. This approach is often found in small enterprises or in industries where a high degree of product uniqueness does not allow for the effective use of automation.

- Partial automation involves the introduction of automated solutions at individual production sites or for specific operations. This includes the use of software-controlled equipment, automated lines at certain stages of production or quality control systems.

- Complex automation is achieved by integrating a variety of automated systems and technologies into a single network that covers multiple production operations and processes. This provides increased coordination and efficiency, and allows production to be automatically adjusted to changing conditions and requirements.

- Full automation means that all aspects of production processes are automated, eliminating or minimising the need for human intervention. These facilities use advanced technologies, including robotisation, AI and machine learning, to manage all operations from raw materials to finished products, ensuring high levels of productivity and quality.

Modern methods of automation of production processes

Modern manufacturing process automation is actively integrating advanced technologies such as artificial intelligence (AI) and machine learning to improve operations and increase efficiency. AI is able to analyse large amounts of data to identify trends and predict potential faults, enabling proactive measures to be taken to minimise downtime and improve product quality. Machine learning, on the other hand, is used to continuously improve processes based on feedback received from manufacturing operations, automatically adapting parameters for optimal results.

The digitalisation of manufacturing and the creation of digital twins opens up new possibilities for modelling and analysing manufacturing systems. A digital twin is a virtual replica of a physical object that allows detailed simulations and testing in a secure virtual environment. This makes it possible to predict potential problems, analyse different scenarios and optimise processes before they are physically implemented.

The application of the Internet of Things (IoT) is transforming manufacturing operations by providing unprecedented levels of data collection and equipment control. With IoT sensors and devices, data on equipment status, temperature, pressure and other critical parameters are collected in real time, enabling real-time monitoring and optimisation of production processes, as well as preventing equipment failures and malfunctions, minimising downtime and losses.

How to implement automation

Implementing automation in production processes requires careful preparation and strategic planning. The first step is a comprehensive analysis of the current state of production, which identifies bottlenecks, inefficient operations and potential areas for automation. This step involves collecting and analysing data on productivity, costs, product quality and lead times.

Based on the information obtained, a detailed implementation plan is created that takes into account the specifics of the company, its production goals and available resources. An important element of the plan is the selection of technologies and equipment best suited to the tasks at hand. At the same time, preference is given to solutions that provide flexibility, scalability and integration with existing systems.

After the selection of technical solutions and automation tools, their adaptation to the specific conditions and processes of the enterprise follows. This stage includes software customisation, hardware modification and creation of specialised interfaces to ensure smooth integration of new systems into the production environment.

A critical aspect of successful implementation of automation is the training of personnel in the use of new systems and technologies. Training should be comprehensive and include both theoretical foundations and practical skills in working with automated systems.

The final stage of implementation includes setting up a quality management system and implementing monitoring and analytics mechanisms to track the effectiveness of automated processes. Regular analysis of indicators and feedback allows timely identification of emerging problems and optimisation of the system, ensuring its continuous improvement and adaptation to changing production conditions.

It is obvious that automation of production processes is a key factor in increasing productivity and reducing costs in modern enterprises. It makes it possible to achieve high precision and repeatability of production, while providing flexibility in changing production tasks.