Flow meter verification

Flowmeter verification is a critical process to ensure the accuracy of measurements in various industries. This process involves thoroughly checking and calibrating different types of flow meters such as turbine, electromagnetic, ultrasonic and vortex meters. Each type requires a unique approach, taking into account its operating principle and accuracy class.

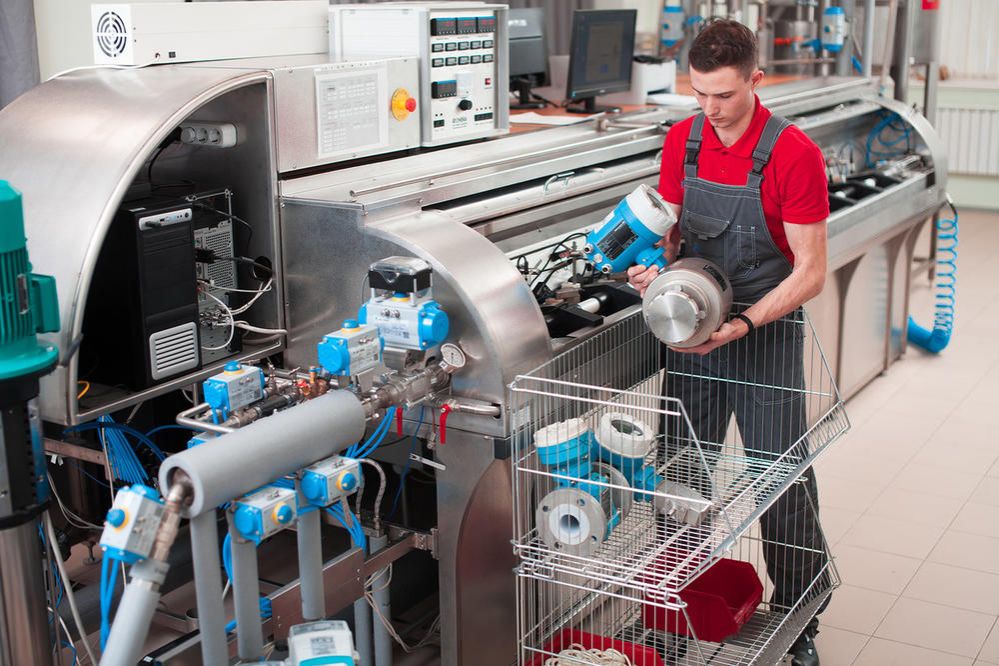

In the process of work, specialists pay special attention to analyzing the operating conditions and specifics of each device.

Verification of flow meters of various types, accuracy and principle of operation

Flowmeter verification is a critical process to ensure the accuracy of measurements in various industries. This process involves thoroughly checking and calibrating different types of flow meters such as turbine, electromagnetic, ultrasonic and vortex meters. Each type requires a unique approach, taking into account its operating principle and accuracy class.

In the process of work, specialists pay special attention to analyzing the operating conditions and specifics of each device.

Flow meter verification: 2 options to choose from

Verification options depend on the specific operating environment and the characteristics of the meters used. In some cases, especially for instruments embedded in complex or critical processes, remote calibration may not be possible due to specific accuracy requirements or data transfer limitations. In these situations, on-site meter testing is the preferred method because it allows technicians to interact directly with the equipment in its operating environment to ensure the most accurate adjustment and adaptation to the operating conditions.

On-site verification of flow meter performance and accuracy

This type of verification allows operators to minimize equipment downtime and avoid the need to dismantle instruments. Promanalit specialists use portable equipment for simulated verification, which allows to simulate various operating conditions and check the response of flow meters to changing flow parameters. This provides in-depth diagnostics of functionality and measurement accuracy without the need to stop production processes. This approach eliminates the risk of damage to the instruments during disassembly and transportation, and reduces the time required for verification.

Remote calibration

Remote calibration involves the use of specialized software to analyze data received from flow meters in real time. Remote calibration allows Promanalit operators to evaluate measurement errors and, if necessary, adjust instrument settings remotely, minimizing interference with equipment operation. This method is ideal for companies that seek to maximize process automation and wish to reduce physical contact in environments with high safety or hygiene requirements.

Procedure and terms of verification of flowmeters

The verification process begins with a thorough visual inspection of the flowmeter by Promanalit specialists to identify any external defects such as cracks, corrosion or other damage that could affect the performance and accuracy of the instrument being serviced. This is followed by analyzing the operation and maintenance history of the instruments to identify any internal wear and tear and malfunctions that may have occurred.

The next step involves a simulated verification, during which experts use calibration benches and modulated operating conditions to accurately assess how effectively the flow meters measure flow in different modes. This procedure makes it possible to identify deviations in performance without having to dismantle or disrupt the production process.

The final stage consists in correcting and adjusting the meters to eliminate the detected errors.This process includes program adjustments, replacing worn components or adjusting the sensitive elements of the devices. The timing of the work depends on the quantity and complexity of the equipment, as well as on the specifics of the work required.

Flow meter verification - quality work of any complexity

Promanalit" company guarantees high quality of flowmeter calibration due to high qualification of its employees, availability of all necessary tolerances and modern equipment. Our specialists in Kazakhstan are regularly trained and upgraded to work with the latest technologies in the field of measurement and calibration. The Promanalit team strives to optimize the flowmeter calibration process to reduce the impact on the customer's production cycle, while ensuring the highest accuracy and reliability of results.

We ensure full transparency and control at all stages of the verification process, providing customers with detailed reports on the work performed and guarantees on the accuracy of measurements achieved.

Choosing Promanalit to verify your flow meters ensures not only accurate measurements, but also confidence in the reliability and efficiency of your production equipment.