Installation of gas analysers

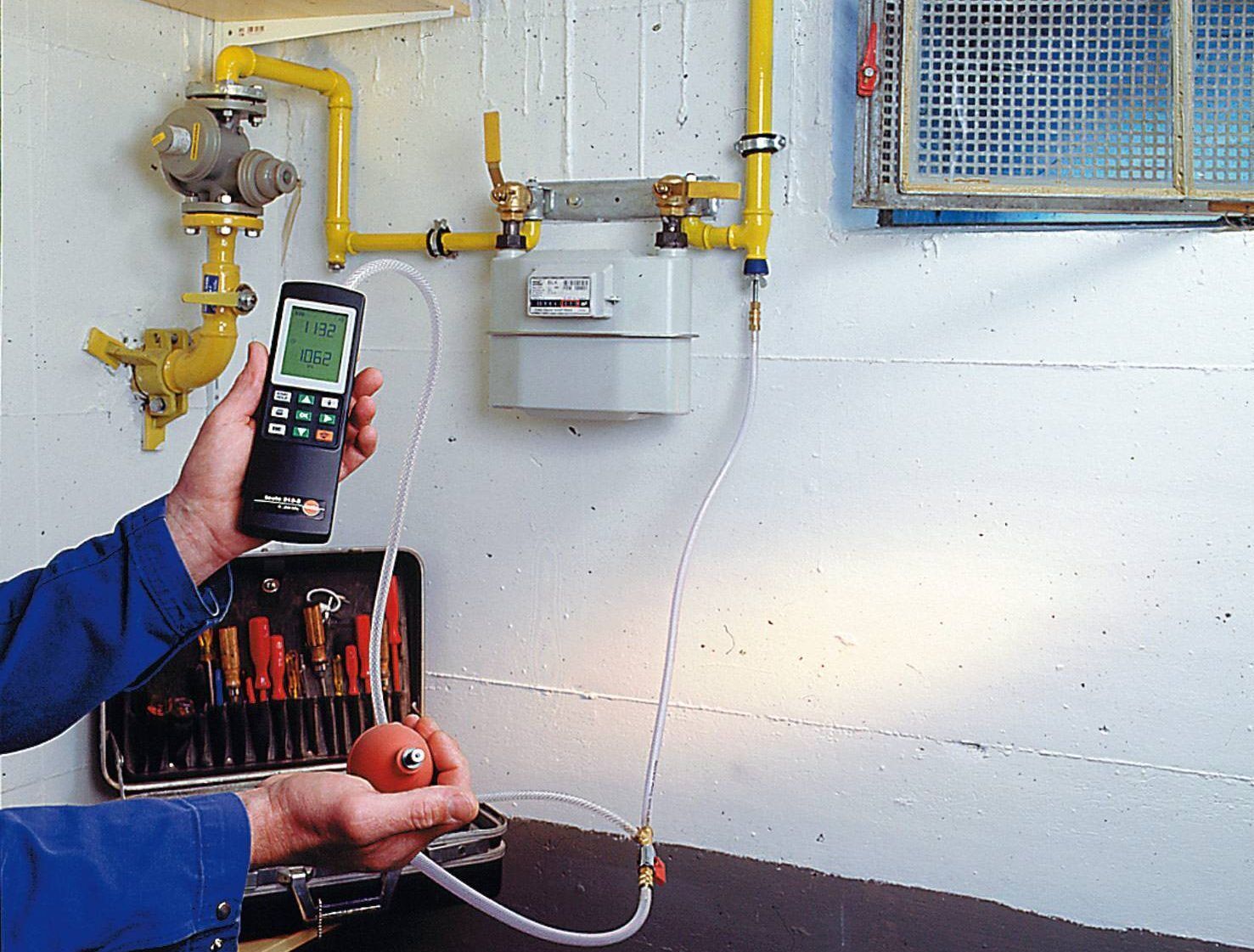

Modern industrial facilities use gas in their operations. This type of fuel is characterised by convenient transportation, environmental friendliness, high calorific value and favourable cost. However, gas leakage often causes an explosion or fire. The solution is to install gas analysers in service areas.

Peculiarities of gas analysing equipment installation

Control of quantitative and qualitative composition and quality of mixtures of hazardous gases in the air is a necessary condition in the operation of any industrial enterprise. Analysing the gas environment is carried out with the help of special measuring devices that allow measuring various particles to determine the presence of harmful additives.

Modern stationary gas analysers automate all processes. This is high-precision measuring equipment capable of providing real-time control of gas concentration in chemical production, industry, construction sites

It can be controlled both at safe distances and remotely. The systems include a variety of sensors capable of capturing any substance. The unified output signal and communication channel allows to receive timely data on the concentration of gassiness, with further activation of ventilation devices and prompt evacuation of workers.

Installation of gas analysers is carried out only by professionals who know all the nuances of devices and their installation. It is important not only to place the equipment competently, but also to adjust its settings correctly.

Installation requirements

All gas analyser installation works are carried out strictly according to the regulations. Since such devices belong to one of the main safety systems, it is necessary to strictly comply with all installation requirements specified in the Technical Regulations, Construction Norms and Rules in force on the territory of the Republic of Kazakhstan:

- The installation of gas detectors is carried out in high-risk locations (high levels of gassiness, emission of a potentially hazardous compound/hazardous vapour);

- light and sound levels are important for the reach of the operating personnel (devices have different signals, and are selected according to sound levels, their extent, depending on the perimeter of closed or open areas);

- With regard to the measuring density, it is important to select a certain mounting height for the sensors;

- when installing the devices, the general fuel composition, the specific location of the building, the characteristics of humidity, temperature, the presence of technical equipment and many other factors are taken into account.

The processes are different, taking into account the specifics of the company's activity. In any case, before installing the gas alarm and the entire system, a detailed analysis of the premises is carried out. This is a guarantee of flawless operation of the devices for a long time.

Installation of gas analysers in production facilities

In closed facilities, compressor sensors are to be installed in places with probable leaks of harmful substances (labyrinth seal, gland and others). The distance is not more than one metre.

In a pumping station, 1 sensor (per pump) is mounted, provided that the horizontal distance is not more than 3 metres.

The sampling device shall be positioned to suit the height of the room.

Gas vent line - pipes having an internal pressure of 6-12 millimetres, with funnels towards the bottom, 50-100 millimetres in diameter. The length of the line is minimal.

The system materials must have anti-corrosion coatings and be unaffected by natural factors and the test substance.

Installation procedure for outdoor installations

The alarm sensor at such facilities is introduced into areas of open system areas where appliances with explosive fuels are located.

The nearest sensor is located from the outer perimeters of the sites at a distance of 8 metres. Placement of rows - in staggered order (shifted by the values of service radii).

The signal detector is mounted at a height from the zero marks up to 1 metre.

Sensor distances for cookers are from 15 metres or more.

On the loading and unloading rack 1 sensor is installed at the zero marks on two tanks simultaneously.

Devices for measuring and signalling up to explosive concentration of flammable gases and vapours - features:

- availability of sound and light alarms;

- explosion-proof designs;

- customised, task-specific settings.

Installation of gas analysers from ‘Promanalit’ company

Promanalit" company offers installation of modern gas analysers in Kazakhstan to solve any set tasks at enterprises of different scale. Specialists will help with the choice of devices of modern modification. All equipment is manufactured in accordance with safety standards and technical requirements. These are heavy-duty stationary and portable gas analysers for control of technological/chemical process in production, safety installations of industrial emission control, combustion, devices for measuring emissions of hydrogen sulphide, methane, ammonia.

All installation work is carried out on a turnkey basis:

- comprehensive service - from installation to customisation and post-warranty service;

- Experienced staff who know how to design effective systems with site analysis in mind;

- Installation of the gas analyser in compliance with all safety requirements and regulations;

- working with chemical gas analysers;

- maintenance, with problems promptly rectified.

You can specify the cost of the service, order installation of gas control systems by calling the phones in the Contacts section.